The Science Behind Modern Tire Technology and Performance

Modern vehicle tires represent a sophisticated blend of engineering, material science, and physics, far exceeding simple rubber rings. They are critical components influencing a vehicle's handling, fuel efficiency, safety, and overall driving experience. The ongoing evolution in tire technology is driven by demands for improved grip, durability, and reduced environmental impact, adapting to diverse road conditions and vehicle types, from conventional combustion engines to advanced electric vehicles. Understanding the intricate design and manufacturing processes behind these essential components reveals how they contribute significantly to vehicle dynamics and passenger comfort.

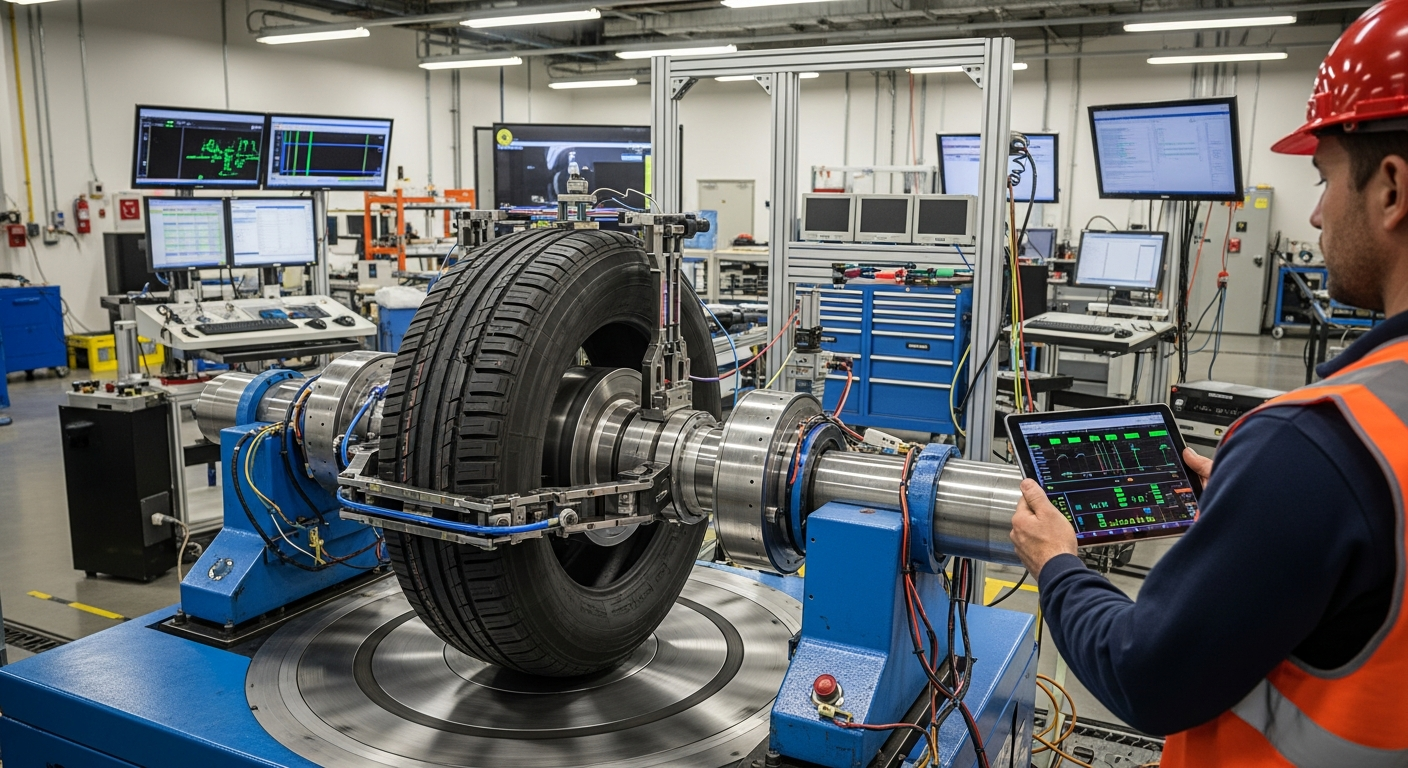

Innovation and Technology in Tire Design

The intricate design of modern tires is a testament to continuous innovation and technological advancements. Engineers meticulously craft tire profiles, tread patterns, and internal structures to optimize performance characteristics. This includes developing specialized rubber compounds, often a complex mixture of natural and synthetic rubbers, carbon black, silica, and various polymers. These compounds are formulated to provide specific properties such as grip on wet and dry surfaces, rolling resistance, and wear longevity. The internal structure, including steel belts and fabric plies, provides strength, stability, and contributes to the tire’s load-carrying capacity and high-speed performance.

Enhancing Driving Performance and Safety

Tire technology plays a pivotal role in a vehicle’s driving performance and safety. The contact patch, the small area of the tire touching the road, is crucial for transmitting forces related to acceleration, braking, and cornering. Advanced tread patterns are designed to efficiently channel water away from the contact patch, reducing hydroplaning risk and enhancing wet grip. Features like sipes and grooves are precisely engineered to improve traction in various conditions, contributing directly to vehicle control and reducing stopping distances. The tire’s ability to absorb road imperfections also impacts ride comfort and stability, which are key aspects of overall vehicle safety.

Manufacturing Processes and Material Science

The manufacturing of modern tires is a highly complex process, integrating advanced material science with precision engineering. It begins with the mixing of raw materials to create the rubber compounds, followed by the assembly of various components such as beads, plies, belts, and treads into a ‘green tire’. This uncured tire then undergoes a vulcanization process under heat and pressure, transforming the soft rubber into a durable, elastic product. Sustainability is increasingly a focus in manufacturing, with efforts directed towards using recycled materials, developing bio-based compounds, and optimizing production to reduce waste and energy consumption. This commitment to sustainable practices extends the lifecycle of tires and minimizes their environmental footprint.

Tire Efficiency and Impact on Fuel and Electric Vehicles

Rolling resistance is a critical factor influencing vehicle efficiency, particularly for both fuel-powered and electric vehicles. It refers to the energy lost when a tire rolls, deforms, and recovers its shape. Tires with lower rolling resistance require less energy to maintain speed, directly translating into improved fuel economy for combustion engines and extended range for electric vehicles. Tire manufacturers are investing heavily in research to develop compounds and constructions that minimize rolling resistance without compromising grip or safety. This balance is crucial for meeting the demands of an evolving automotive landscape that prioritizes energy efficiency and reduced emissions.

Future Trends in Mobility and Road Automation

The future of mobility, characterized by electric vehicles, autonomous driving, and connected cars, places new demands on tire technology. Tires are evolving to become ‘smarter,’ incorporating sensors that monitor pressure, temperature, and wear in real time, providing valuable data for vehicle maintenance systems and enhancing safety. These smart tires can also communicate with the vehicle’s onboard computer and even road infrastructure, contributing to the development of advanced driver-assistance systems and fully autonomous vehicles. The design of tires for future vehicles will also need to consider specific requirements like increased torque from electric motors and the unique weight distribution of battery packs, ensuring optimal performance on diverse road surfaces.

Vehicle Maintenance and Tire Longevity

Proper vehicle maintenance, particularly concerning tires, is essential for maximizing their longevity and ensuring consistent performance. Regular checks for tire pressure, tread depth, and overall condition are fundamental. Incorrect tire pressure can lead to uneven wear, reduced fuel efficiency, and compromised handling and safety. Routine tire rotation helps distribute wear evenly across all four tires, extending their useful life. Wheel alignment and balancing are also crucial to prevent premature wear and maintain a smooth, stable ride. Adhering to manufacturer recommendations for tire care can significantly enhance the operational lifespan of tires and contribute to the overall safety and efficiency of the vehicle.

Modern tire technology is a continuously evolving field, driven by scientific breakthroughs and the changing demands of the automotive industry. From the molecular structure of rubber compounds to advanced manufacturing techniques, every aspect is designed to deliver optimal performance, safety, and efficiency. As vehicles become more sophisticated, the role of tires will only grow in complexity and importance, integrating further with vehicle systems to enhance the overall driving experience and contribute to a sustainable future for transport.