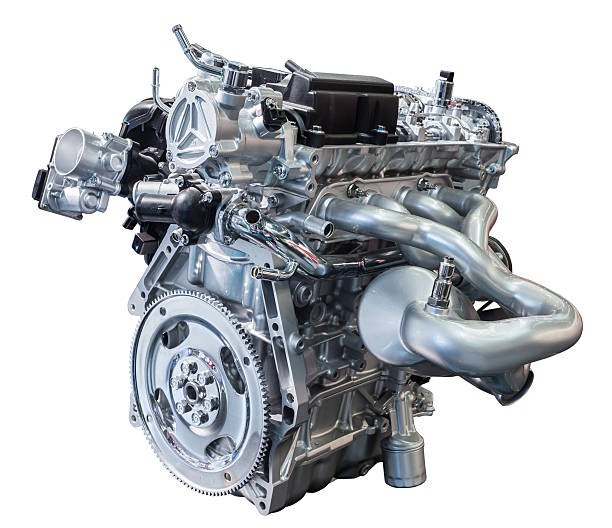

Microbubble Lubrication: The Next Frontier in Engine Efficiency

In the relentless pursuit of automotive efficiency, engineers have explored countless avenues to reduce friction and enhance engine performance. But what if the key to unlocking unprecedented levels of efficiency lies in something as simple as tiny bubbles? Welcome to the world of microbubble lubrication, a cutting-edge technology that's poised to redefine the boundaries of engine design and performance.

The concept draws inspiration from nature, particularly the ability of certain fish to secrete mucus containing microbubbles, allowing them to swim more efficiently. Researchers have spent years translating this biological phenomenon into a practical automotive application, overcoming challenges such as bubble stability and uniform distribution within the oil.

Advantages Over Traditional Lubrication Methods

Traditional engine oils rely solely on the liquid’s viscosity to reduce friction. While effective, this approach has limitations, particularly at high temperatures and pressures. Microbubble lubrication, on the other hand, offers several distinct advantages:

-

Enhanced Friction Reduction: The air cushion provided by microbubbles can reduce friction by up to 30% compared to conventional oils.

-

Improved Heat Dissipation: Microbubbles help distribute heat more evenly throughout the engine, preventing hot spots and reducing overall operating temperatures.

-

Extended Engine Life: With less metal-to-metal contact, engine components experience less wear, potentially doubling the lifespan of critical parts.

-

Increased Fuel Efficiency: Lower friction translates directly to improved fuel economy, with early tests showing gains of 5-8% in fuel efficiency.

Implementation Challenges and Solutions

While the potential of microbubble lubrication is immense, its implementation has not been without challenges. One of the primary hurdles has been maintaining bubble stability under the extreme conditions inside an engine. Researchers have tackled this issue by developing specialized surfactants that coat the bubbles, preventing them from coalescing or dissipating too quickly.

Another challenge has been the uniform distribution of microbubbles throughout the engine oil. Advanced injection systems and oil circulation designs have been developed to ensure that bubbles are consistently present where they’re needed most, such as in bearings and between piston rings and cylinder walls.

Real-World Applications and Early Adopters

Several major automotive manufacturers have begun incorporating microbubble lubrication technology into their research and development programs. While still in the testing phase for many, a few high-performance vehicles have already hit the market with this technology, showcasing its potential.

One notable example is a limited-edition sports car that uses a microbubble lubrication system in its high-revving V8 engine. The manufacturer reports a 7% increase in horsepower and a 9% improvement in fuel efficiency compared to the same engine with conventional lubrication.

The Future of Microbubble Lubrication

As the technology matures, we can expect to see microbubble lubrication become more widespread across the automotive industry. Its potential extends beyond just internal combustion engines; electric vehicles could also benefit from reduced friction in their drivetrains and cooling systems.

Moreover, the principles of microbubble lubrication are being explored in other industries, from industrial machinery to renewable energy systems. This cross-pollination of ideas could lead to even more innovative applications and improvements in the automotive sector.

Environmental Impact and Sustainability

One of the most promising aspects of microbubble lubrication is its potential environmental impact. By improving fuel efficiency and extending engine life, this technology could significantly reduce the carbon footprint of vehicles. Additionally, the reduced wear on engine components means less frequent oil changes and fewer replacement parts, further minimizing waste.

Researchers are also exploring bio-based surfactants for creating and stabilizing microbubbles, making the entire system more environmentally friendly. This aligns well with the automotive industry’s broader push towards sustainability and reduced emissions.

Challenges in Mass Adoption

Despite its promise, microbubble lubrication faces several hurdles before it can become a standard feature in vehicles. Cost is a primary concern, as the technology currently requires specialized oils and engine modifications. There’s also the challenge of educating consumers and mechanics about the benefits and proper maintenance of microbubble lubrication systems.

Regulatory bodies will need to evaluate and approve the technology for widespread use, a process that can be time-consuming but is crucial for ensuring safety and reliability. As with any new automotive technology, long-term durability and performance data will be essential for gaining consumer trust and industry acceptance.

Conclusion: A Bubble-Powered Future

Microbubble lubrication represents a fascinating convergence of biology, physics, and automotive engineering. As the technology continues to evolve, it has the potential to redefine our expectations of engine performance, efficiency, and longevity. While challenges remain, the automotive industry’s growing focus on innovation and sustainability suggests that microbubble lubrication could become a standard feature in vehicles of the future, ushering in a new era of engine efficiency powered by the humble bubble.